What’s the best way to get custom display racks and reduce lead time without breaking your budget? Here are 4 tips to help you.

In the current environment, we can see a trend towards shortening the deadlines for purchasing display racks and in-store marketing plans. In addition, competition among retailers is becoming increasingly fierce, which is increasing financial pressure on the industry, and the pace of product innovation is accelerating. This jointly reduces the retail store’s display rack planning scope and production delivery time.

Therefore, here are the following 4 suggestions for ways to reduce delivery time without increasing funds:

1) Clearly describe the display rack you need to purchase

Because everyone’s understanding ability is different, the description and definition of the display stand are different. This often results in a lot of time being wasted on communication, so the best way is to describe in points, including:

1. Product size, gross weight, net weight

2. Product pictures

3. Dimensions of the required display stand (length*width*height mm)

4. Purchase quantity

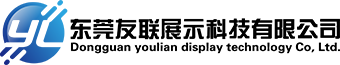

5. Are there drawings, CAD or dead 3D drawings?

6. The number of SUK for each part of the display stand, such as hooks, how many layers, how many casters/flat pads, etc.

6. Color and material requirements

7. Packaging requirements

2) If you have drawings, please sort them out and prepare them in advance.

Whether it is CAD or 3D, it should be sorted and packaged and sent to the supplier. The logo, pattern, texture and other documents on the display shelf also need to be sorted and sent together, in the form of vector artwork in PDF, EPS, AI or other formats Submissions in accepted formats are best.

The biggest reason for doing this is to minimize the back-and-forth communication time between the publicity design team and our printing team. The faster some details are confirmed, the faster production proofing can be finalized.

3) Keep the sample production time as short as possible

As much as possible, common materials on the market can be used to shorten the time for purchasing raw materials, thereby reducing the time for shelf sample production. Of course, the drawings provided to the manufacturer are clear and complete, and can be produced directly according to the drawings, saving engineers the time of designing and producing drawings, thereby shortening the proofing time.

4) Make a smart and fast shipping plan

The development of a clear shipping plan is really important with tight deadlines. Negotiate with the customer about the method of transportation and whether to use your own freight forwarder or a supplier to help with transportation. One more thing, if you need to launch a national program, think of delivery locations in advance to meet customer requirements.

Assuming you are shipping from the West Coast, you may want to decide on the best way to ship to an East Coast store since the shipping route to the West Coast store will be shorter. At the same time, you need to know how these products will be packaged and shipped. In terms of packaging, whether it is KD packaging or overall packaging, whether it is pallet packaging or carton packaging; whether it is to be delivered by UPS, FEDEX or DHL, these all need to be negotiated in advance and considered clearly, which is very important.

It is also very important to confirm a high-quality freight company. It is best to have goods that you are familiar with, and the emphasis is on efficiency and speed. We will choose whatever is convenient, simple and fast.

Generally speaking, samples are shipped by air because it is necessary to quickly confirm that the samples are correct for mass production.

Post time: Sep-15-2023